Tungsten Inert Gas (TIG) Welding

GENERAL

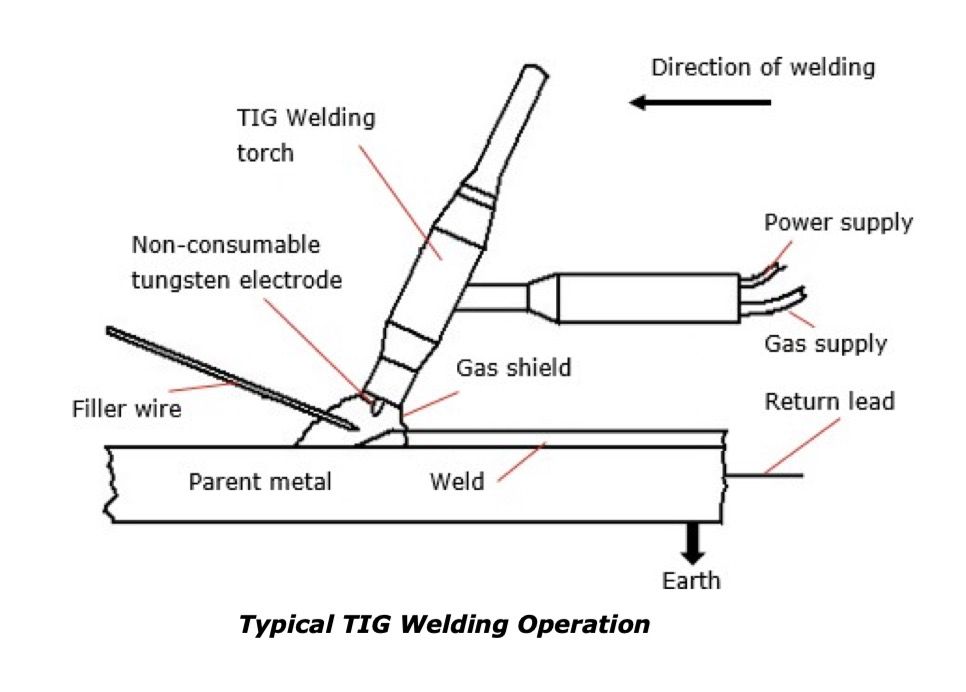

The TIG welding process uses a non-consumable tungsten electrode to provide an arc. Filler metal, when required, is fed from a separate filler rod in a manner similar to oxy-acetylene welding. A shielding gas, e.g. argon, is fed through the welding gun to the weld area and provides a gas shield to prevent contamination by the atmospheric gases. No fluxes are used with the process.

To produce the weld, without the addition of separately fed filler wire, the process is known as autogenous TIG.

Although initially developed for the light alloys, i.e. aluminium and magnesium, TIG welding may be used on a large variety of metals particularly those with high oxidation rates.

The manual TIG process is expensive when compared to most other manual arc welding techniques and is generally only used on carbon steels when high metallurgical and mechanical properties are required for the weld. An example application is for the deposition of high quality root runs on pipework; the fillers and cap are usually deposited by a more cost effective process such as MMA or MAG.

When high quality root runs are to be deposited, a back purge* is used to prevent oxidizing (coking) of the weld metal. When access to the weld area is difficult, e.g. with deep vee preparations or corner welds, the tungsten electrode stick-out length can be increased providing a gas lens is fitted to stiffen the gas shield to prevent turbulence, which would otherwise lead to oxidation of the weld metal.

Back purge*: displacement of atmosphere with inert gases.

It is possible to automate the TIG process and many systems are in current use, particularly on pipe where the welding head travels on fixed rings around the joint, the electrode may be stationary or may oscillate from side to side. On root beads it is usual to pulse the current to control the penetration

Tungsten electrode

There are two classifications for tungsten electrodes:

-

Plain (un-activated) tungsten - Plain tungsten electrodes tend to laminate in use and can cause tungsten inclusions in the weld. This type of electrode is rarely used and is suitable for lower quality general purpose welds on all metals.

-

Activated tungsten - The addition of either thoria or zirconia to the tungsten gives considerable advantages including increased electron emission for better arc striking, re-ignition and stability, particularly with low current values. There is also a reduction in the possibility of tungsten inclusions in the weld.

1% Thoriated tungsten electrodes: used with electrode DC -ve for the welding of all metals except the light alloys (aluminium and magnesium).

2% Thoriated tungsten electrodes: as above, but for applications where lower amperages are used and improved arc stability is required. Thorium is radioactive so thoriated tungsten electrodes produce ionising radiation.

Other activators now available include cerium and lanthanum.

Zirconiated tungsten electrodes are specifically used with AC for the welding of the light alloys.

Selection of current type

In selecting the type of current to be used for TIG welding, consideration has to be given to the material being welded and the requirements of the arc. Sometimes arc stability is of prime importance, but occasionally the removal of surface oxide, i.e. a cleaning action, takes priority.

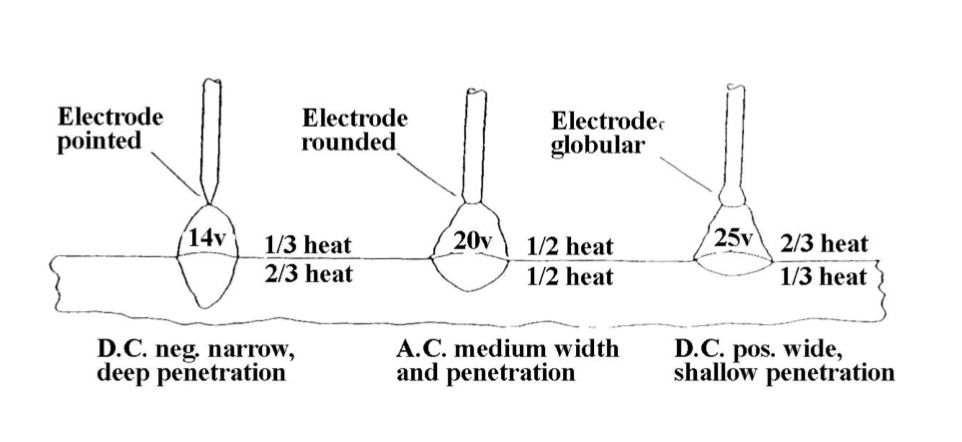

Tungsten has good ionization potential, i.e. electrons and therefore current flow, are easily produced; this produces an inherently stable arc. Electrons flow from negative to positive, therefore natural stability will also be achieved with electrode DC -ve, however, because most metals have some natural ionization potential, then stability will also result with electrode DC +ve, but the arc voltage will be higher.

When the electrode is negative it is at the cool end of the arc; when it is positive it is at the hot end of the arc.

Tungsten electrodes usually require a clean sharp tip to be maintained during welding. Welding with electrode DC +ve can overheat and melt the tip, which becomes globular in shape resulting in an uncontrolled arc and possible tungsten inclusions in the weld metal.

For most metals electrode DC -ve is used, the exceptions are aluminium, magnesium, and their alloys. The welding of the light alloys requires an electric arc which is capable of removing the oxide film which has a higher melting point than the material from which it was formed.

There is a scavenging action achieved with electrode DC +ve which does not exist with DC -ve, therefore from a cleaning point of view, this connection is the one most suitable for the welding of the light alloys. However, electrode DC +ve polarity will melt the electrode tip as stated earlier, unless a low current with a very large electrode is used, but this is unsuitable as it creates an unstable arc.

A compromise is met by using alternating current, so that for 50% of each current cycle the electrode is positive, therefore cleaning and welding takes place, and for the other 50% of the time the electrode is negative and is cooled down, therefore melting of the electrode is prevented. In AC arcs, because of the reversal of polarity, the heat distribution is even.

Protection of the molten pool

The gas shield fulfils two main functions:

- It provides a suitable ionizable atmosphere for the electric arc.

- It protects the weld pool from atmospheric contamination.

Gas type and gas flow rates are important considerations. Excessive gas pressure can cause rippling of the weld pool and give a coarse finish to the weld bead.

Three gases may be considered for TIG welding: argon, helium, and nitrogen.

1. Argon

The inert gas argon provides a very cost effective gas shield for all metal types, it produces a smooth, quiet arc with low arc volts which makes it ideal for light gauge material or positional welding. It improves the cleaning action when used with AC on light alloys.

The addition of between 1% and 5% of the active gas hydrogen will raise the arc voltage and give deeper penetration or increased welding speed on stainless steel, or on carbon steels that can accept the extra hydrogen content in the weld/HAZ.

2. Helium

The inert gas helium is lighter than argon, therefore requires higher flow rates (2 to 2.5 times) to give the same effective shielding. Helium creates a higher arc voltage which is useful for welding thick sections and metals with a high thermal conductivity. When used with AC on the light alloys there is less cleaning action when compared to argon. Helium is also more expensive than argon.

3. Nitrogen

Inert at room temperature, nitrogen combines with oxygen at arc temperatures and becomes active, therefore it is unsuitable for the majority of metals but gives good results on copper as it increases arc voltage which creates more heat and is far more cost effective than argon or helium.

Filler material

The filler material used for TIG welding should conform to BS EN ISO 14341Welding Consumables. Wire Electrodes and Deposits for Gas Shielded Metal Arc Welding of Non Alloy and fine Grain Steels (or other national/international specifications).

Because of the porosity problems which can occur when welding carbon steels with the TIG process, killed or fully deoxidized wire–such as silicon manganese–should be used. For very high quality welds, triple deoxidized silicon/manganese/aluminium wire is recommended.

Power source requirements

A high OCV* of around 90 volts is required for TIG welding to ensure arc stability at all times. The power source, which may be a generator, transformer or transformer-rectifier must be of a drooping characteristic to maintain a relatively constant current value, the operator being responsible for arc length control.

*OCV = Open Circuit Voltage

To assist arc initiation, to prevent tungsten inclusions in the weld and to prevent damage to the electrode tip, a high voltage, high frequency current is superimposed at the start of all DC welding operations. These characteristics are permanent when AC is used, to assist arc re-ignition at the beginning of each positive half cycle.